Software

The proposed system consists of a P.L.C. and a P.C. on which dedicated software for the specific production line is installed.

The software, developed by us in a Windows environment, is capable of supervising the line in all its typical parameters (bar positions, temperatures, currents, etc.) and can interact by modifying these parameters. All the software and hardware used are of standard type and easily available in the market. There is the possibility of networking the P.C. with the factory network, subject to the definition of the mode and data to be exchanged.

In order to facilitate data exchange between various parts of the plant from different manufacturers, the use of the Profibus fieldbus is proposed. This Siemens proprietary system allows our P.L.C. (Master) to participate in certain data areas in the P.L.C. Slaves. This allows individual machines to work autonomously.

For safety purposes, some signals will be exchanged between the various machines using electrical contacts rather than the bus.

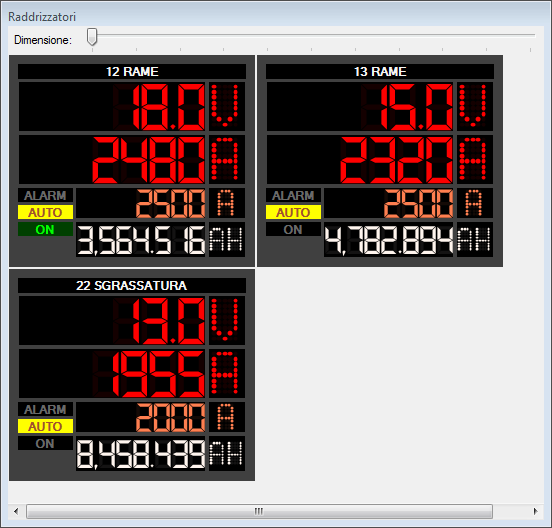

CONFIGURATION

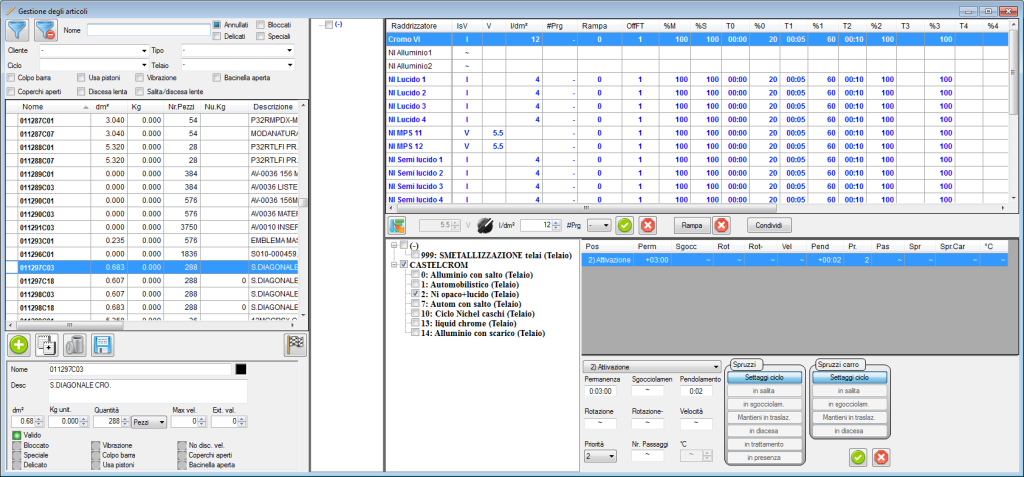

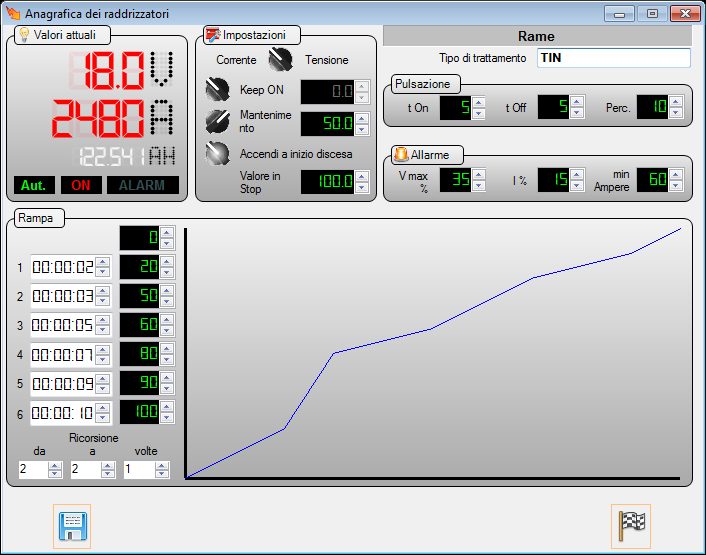

To make the software easily reusable for future applications and adaptable in case of modifications, there are several pages where the plant’s main components can be configured:

Number and type of tanks Number of carts Number and type of rectifiers Number and positions of multiple washes Dosers and the positions they work on Number of temperature controllers and the positions they work on

RTICLE DATABASE

An article database can be created to manage typical pieces of treatment data:

Piece recognition code Finish type Treatment times in electrolytic baths Currents for electrolytic baths Ideal bar load Surface area of each piece (for calculations)

PLANT SYNOPSIS

A page is provided that displays the plant layout with carts, bars, etc., in a stylized manner.

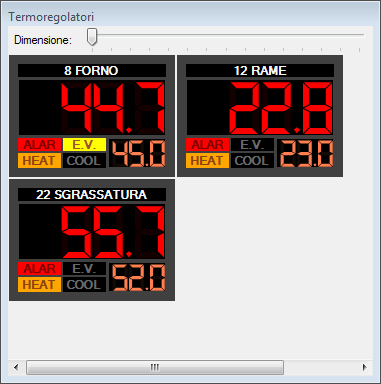

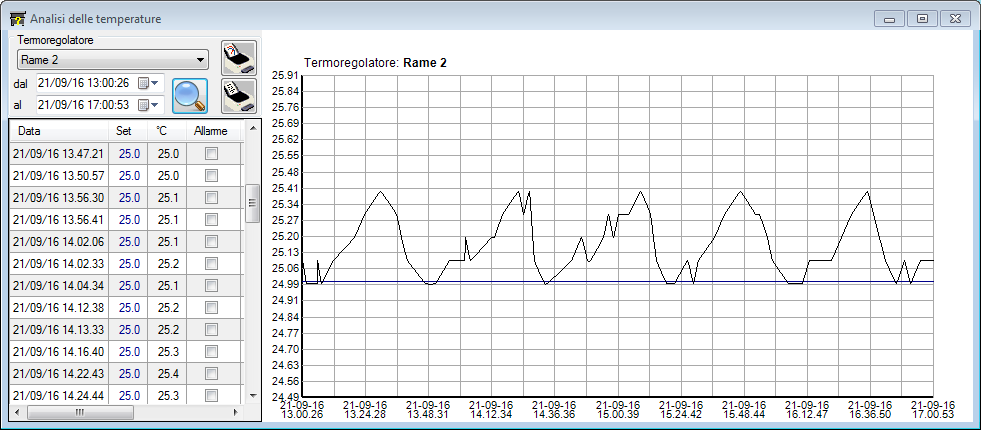

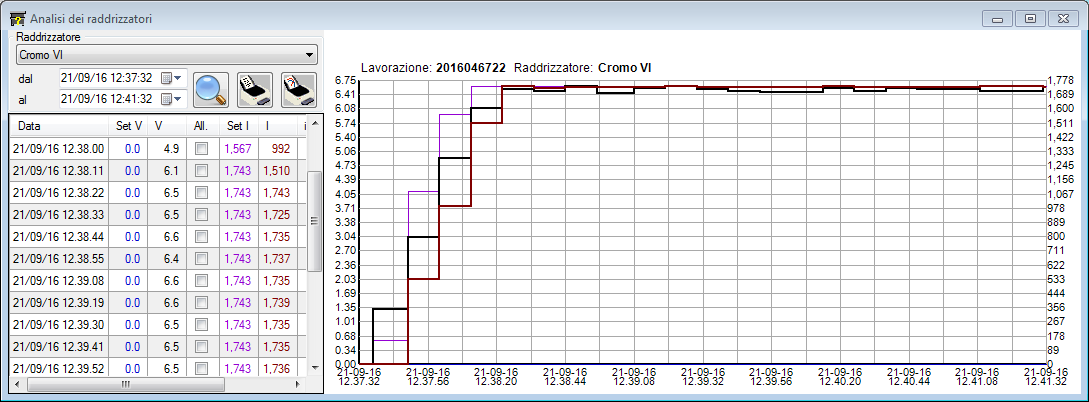

TEMPERATURE

Dynamic temperature data is displayed graphically and in tabular form for temperature regulation.

Alarm thresholds (min. and max.) and the working value can be set.

All temperature-related data is stored in a database and made available for tabular viewing or in the form of diagrams.

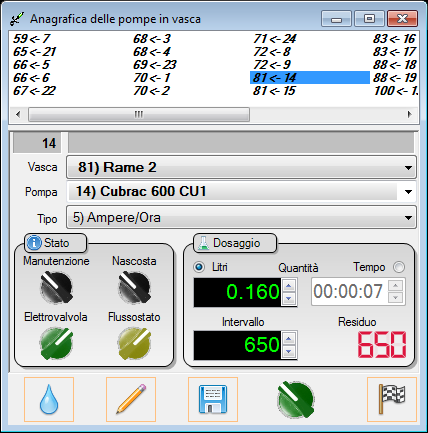

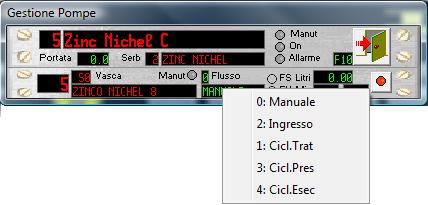

DOSERS

The dosers on the line will be configured, indicating:

Activation threshold

Quantity of material to be added to the baths

The operation of the dosers is displayed dynamically, showing the on and off times.

Whenever dosing is performed, its value is archived for statistical purposes.

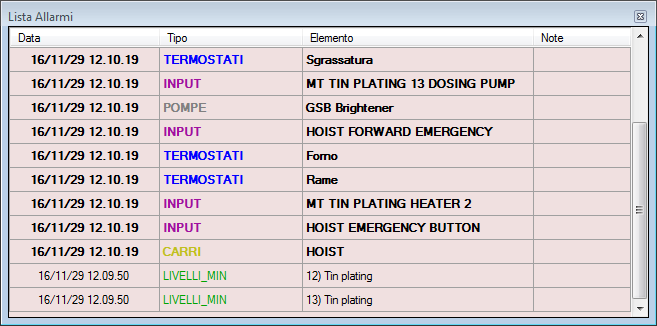

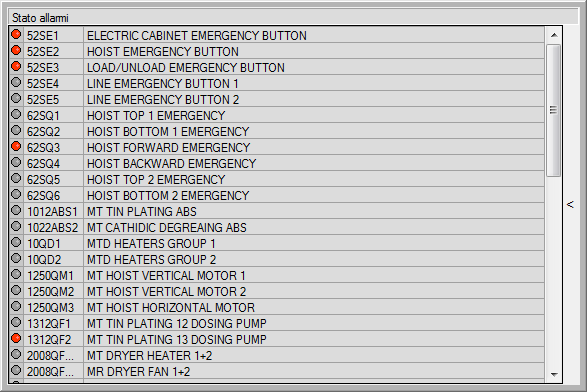

Alarms

For alarm management, ISA 1A standards are used, including acoustic and visual alarms, along with detailed on-screen notifications.

An alarm log is generated and can be consulted even after some time has passed.

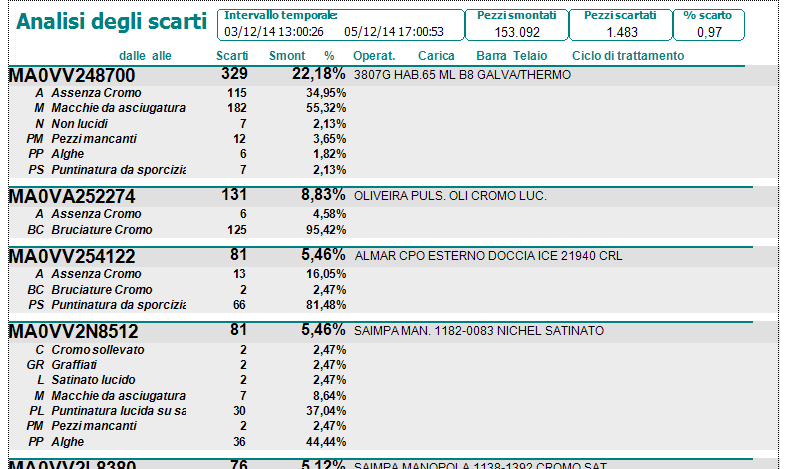

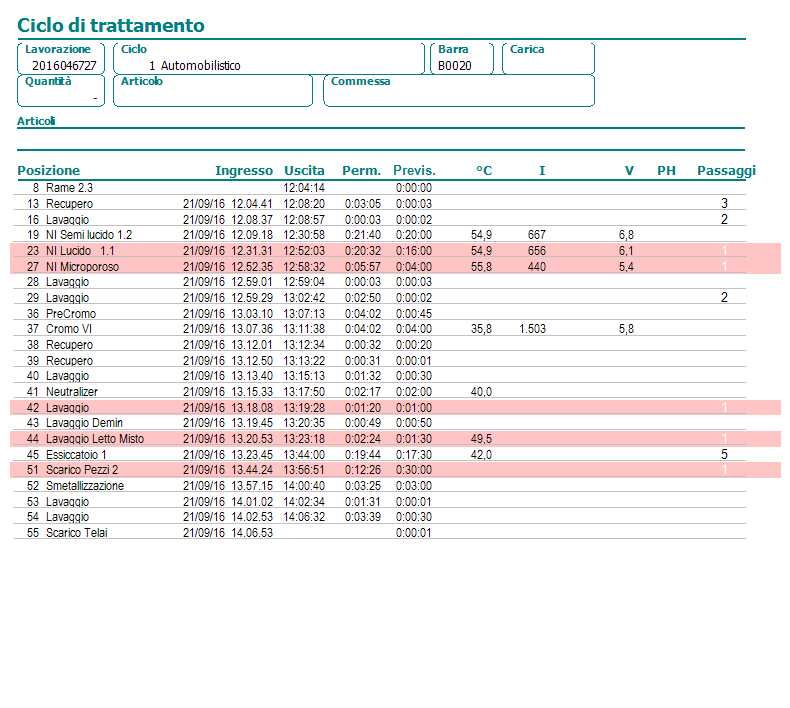

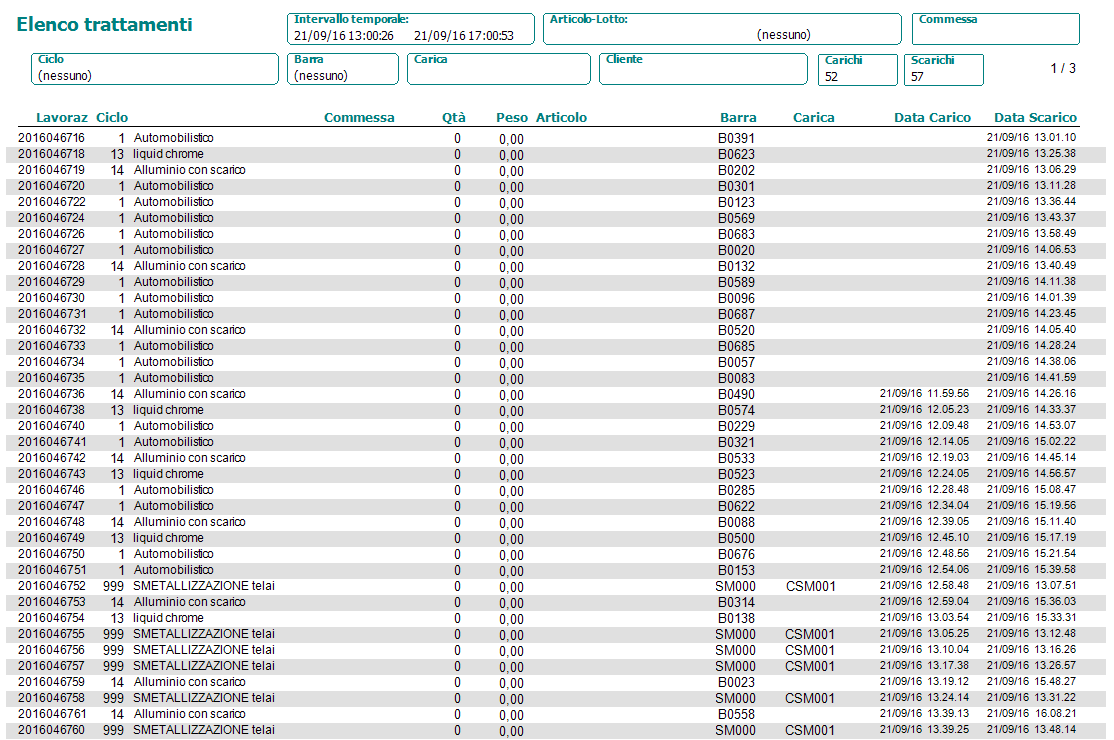

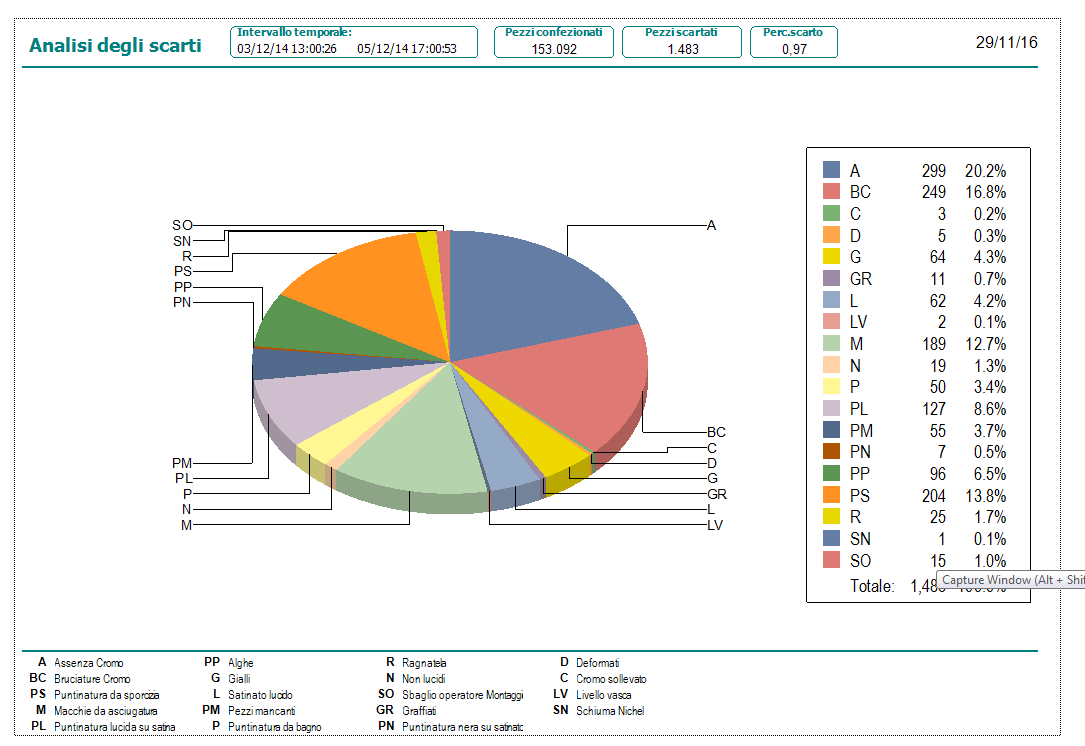

PROCESS STATISTICS

Given the powerful database supervising the galvanic line, it is possible to obtain data related to:

Analysis of rejects and quality verification of the treatment History of the processing the piece has undergone Verification of the actual utilization of each treatment bath

LEGALE